You have no items in your shopping cart.

Bike Bearing Guide

Shockcraft is the largest stockist in NZ for bike bearings & bushings. We supply retail, we supply bike shops and we even supply bearing stores.

As well as offering bearings in a massive assortment of sizes, we have a huge range of types. Here's what they are and what they mean.

Deep Groove Bearing (600 & 6000 Series)

This is what most people know as a cartridge bearing. Two races, balls with grease inside and usually seals on the outside. Codes start with 6 for metric bearings. MR are special metric sizes, DR is double row. They take load best straight up and down. You will find them in bike hubs and bottom-brackets.

Angular Contact Bearing (7000 Series)

These can look like a Deep Groove bearing but are designed to better take thrust loads in one direction. Sometimes they look like normal deep groove bearings but the bearing codes start with a 7 instead of a 6. Look closely and you'll see the inside race is a cone shape and the outside race looks like a cup shape. The bike industry has a whole range of angular contact bearings with chamfered races for head-set application. Some hub, BB and frame manufacturers specify angular contact bearings too. Usually for the wrong reasons.

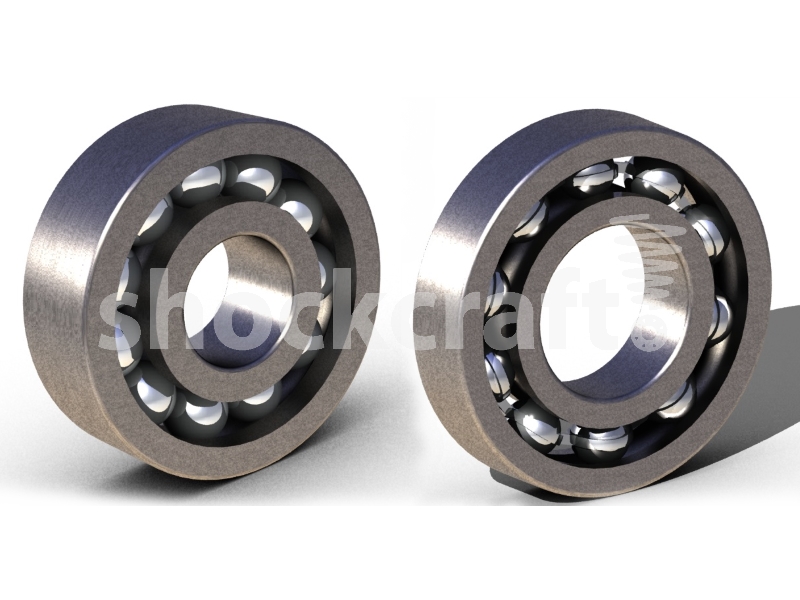

Full Complement Bearing (FC, V or MAX Codes)

These are a special type of Deep Groove Bearing. Instead of having a cage inside (bearing on right) to separate the balls (and stop them grinding on each other) they are packed completely full of balls (photo on left). Usually have just under twice as many as a Deep Groove bearing of the same size. In MTB they are used in rear suspension pivots. Because they're stronger for the size and with short rotation they push grease to the next ball better. Don't put them in hubs or BB, they'll wear out fast as the balls rub.

These are a special type of Deep Groove Bearing. Instead of having a cage inside (bearing on right) to separate the balls (and stop them grinding on each other) they are packed completely full of balls (photo on left). Usually have just under twice as many as a Deep Groove bearing of the same size. In MTB they are used in rear suspension pivots. Because they're stronger for the size and with short rotation they push grease to the next ball better. Don't put them in hubs or BB, they'll wear out fast as the balls rub.

Stainless Steel Bearings

Normal steel bearings are made from a super-hard chromium bearing steel. Stainless bearing steel (440C) is a bit softer but much more corrosion resistant. The seals are also a bit tighter. If you are killing bearings from rust then they will help. But if you're wearing out bearings in dry conditions they might not last as long.

Ceramic Hybrid Bearings

These have ceramic balls and chromium steel races. They were originally designed as electrical insulating bearings but are slightly lighter so the bike industry got hold of them. Best for dry only conditions as the seals don't really touch and grease fill is low.

So What Do You Fit?

BB and hubs in dry conditions – Deep Groove steel bearings. BB and front hub in damp conditions – Stainless steel bearings. Headset in dry conditions – Angular contact steel bearings. Headset in damp conditions – Angular contact stainless steel bearings. Suspension pivots – Full complement bearings

Grease Fill

It's usually 20-30% on new bearings. Can be even less on Ceramic Hybrids.

Extra Grease

Only do this on new bearings or bearings that have been completely cleaned out. For BB and Hub you don't want more than 50% grease fill (remove one seal and fill the void, replace the seal) otherwise it creates extra drag and can pop the seals off in the cold. For headset and suspension pivot bearings feel free to pack in as much grease as you can.

Grease Types

Thicker protects better but has more drag. Motorex Bike Grease 2000 is an excellent fully waterproof grease for greasing steel bearings. Slickoleum is a low viscosity suspension grease that works great in bearings for less drag. Avoid grease with particles (PTFE, Molybdenum etc) as these have lumps the balls need to climb over. Those greases are only for coarse sliding surfaces.